Why Track Procurement Performance?

Effective procurement is a cost‑saving engine for any organization. By measuring performance you can:

- Identify savings opportunities before they disappear.

- Benchmark suppliers and internal processes against industry standards.

- Prioritize improvement initiatives with data‑driven confidence.

- Show the strategic value of procurement to senior leadership.

Core Procurement Performance Metrics

Below are the eight most commonly‑used metrics. Each includes a brief definition, why it matters, and a simple way to calculate it.

1. Product Price Variance

What it measures: The gap between the contract unit price you pay and an external reference price (e.g., market index).

Why it matters: Highlights over‑paying and helps negotiate better pricing.

Formula: ((Contract Price – Reference Price) ÷ Reference Price) × 100%

2. Effective Contract Utilization

Tracks the percentage of spend that runs under an existing contract versus ad‑hoc purchases.

- Higher utilization = better leverage of negotiated terms.

- Measure for purchase orders, annual contracts, and multi‑year contracts.

3. Expiration Management of Procured Products

Measures the value of goods that expire before use.

- Expressed as

(Expired Spend ÷ Total Spend) × 100%. - Break down by category (e.g., donated items for non‑profits).

4. Supplier Performance

Aggregates delivery quality, timeliness, and compliance.

- Use a scorecard (on‑time % + quality % + compliance %) / 3.

- Identify under‑performing suppliers for corrective action.

5. Procurement Cycle Time

Average number of days from requisition to purchase order issuance.

Formula: Total Days of All Cycles ÷ Number of Cycles

6. Payment Processing Time

Percentage of invoices paid within agreed payment terms.

Formula: (Invoices Paid On‑Time ÷ Total Invoices) × 100%

7. Emergency Procurement Ratio

Share of spend that occurs under emergency conditions.

Formula: (Emergency Spend ÷ Total Spend) × 100%

8. Procurement Cost per Order

Total internal cost (staff, systems, overhead) divided by the number of orders processed.

Formula: Total Procurement Cost ÷ Number of Orders

Industry‑Specific Examples

Manufacturing

- Price variance: Compare steel purchase contracts to the London Metal Exchange price.

- Cycle time: Target ≤ 5 days for critical component orders to keep the production line moving.

Healthcare

- Expiration management: Track expired pharmaceuticals; aim for < 1% expiration rate.

- Supplier performance: Use sterility and on‑time delivery as key criteria.

Non‑Profit / Humanitarian Aid

- Donated product expiry: Measure the % of donated food that expires before distribution.

- Emergency procurement: Proportion of disaster‑relief spend vs. regular spend.

How to Build a Simple Procurement Metrics Dashboard

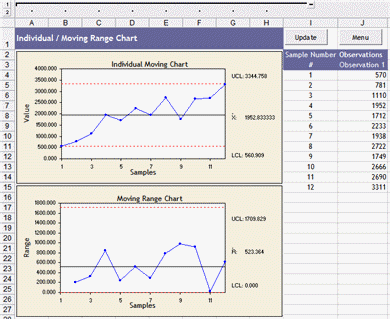

Use an Excel‑based dashboard to visualise the metrics above. The steps are:

- Collect raw data from ERP, spend analysis tools, and supplier scorecards.

- Standardise fields (date, supplier, product, cost, status).

- Create a master table that feeds each metric calculation.

- Use Financial Dashboard Excel templates for charts and traffic‑light indicators.

- Refresh the data monthly and review trends with the procurement team.

Sample Metric Table

| Metric | Formula | Data Source | Target |

|---|---|---|---|

| Product Price Variance | ((Contract – Reference) ÷ Reference) × 100% | Contract database + market index | < 5% |

| Contract Utilization | (Spend Under Contract ÷ Total Spend) × 100% | Spend system | > 80% |

| Expired Spend | (Expired ÷ Total) × 100% | Inventory management | < 1% |

| Supplier On‑Time Delivery | (On‑Time Deliveries ÷ Total Deliveries) × 100% | Logistics system | > 95% |

| Procurement Cycle Time | Total Days ÷ Number of Purchases | ERP requisition module | < 7 days |

| Payment Processing Time | (Invoices Paid On‑Time ÷ Total Invoices) × 100% | Accounts Payable | > 90% |

| Emergency Procurement Ratio | (Emergency Spend ÷ Total Spend) × 100% | Spend system (tagged emergencies) | < 5% |

| Cost per Order | Total Procurement Cost ÷ Number of Orders | Finance + Procurement | Reduce 10% YoY |

Next Steps

Start by picking three metrics that matter most to your organization. Build a simple Excel sheet using the table above, then review the results with your team. As you gain confidence, expand to the full set of eight metrics and integrate them into a strategic scorecard.

Looking for a ready‑made framework? Explore the Balanced Scorecard and Strategy Map Toolkit to turn these metrics into a strategic dashboard that aligns procurement with overall corporate goals.