Introduction

Customers gravitate toward businesses that consistently deliver high‑quality products and services. A process‑based Quality Management System (QMS) provides the structure needed to sustain that consistency, avoid costly rework, and protect a company’s competitive edge over the long term.

What Is a Process‑Based QMS?

A process‑based QMS views every activity—from design to delivery—as a linked series of processes. Each process is defined, measured, and continuously improved. This approach shifts the focus from isolated inspections to systematic control of the entire value stream.

- Design Quality Requirements – Minimum specifications a product or service must meet before it reaches the market.

- Process Quality Requirements – Operational standards that ensure every step produces results that satisfy the design criteria.

- Customer‑Focused Targets – Benchmarks set slightly higher than expected to create a buffer of excellence.

Key Benefits of a Process‑Based QMS

- Higher customer satisfaction and loyalty

- Reduced waste, scrap, and re‑work costs

- Clear responsibility and accountability across teams

- Easier compliance with ISO and industry‑specific standards

- Scalable framework for rapid growth and new product launches

Core Components & Templates

Below are the essential building blocks of a robust process‑based QMS, each with a ready‑to‑use template.

1. Process Map (Flow Diagram)

Visualize the end‑to‑end workflow. Use swim‑lane diagrams to assign ownership to each step.

2. Standard Operating Procedure (SOP) Template

Document the exact steps, inputs, outputs, and quality checks for each process.

SOP Title

Purpose: Scope: Responsibility: Materials & Tools: Step‑by‑Step Instructions: Control Points & Acceptance Criteria: Records & Documentation: Revision History:

3. Process Control Sheet

Track daily performance against key metrics (e.g., cycle time, defect rate).

| Date | Process | Target | Actual | Variance | Comments |

|---|---|---|---|---|---|

| 2024‑07‑01 | Assembly | 95% | 93% | -2% | Minor tooling wear |

| 2024‑07‑01 | Inspection | 99% | 99% | 0% | Within spec |

Industry‑Specific Examples

Manufacturing

- Process: Raw material receipt → CNC machining → Heat treatment → Final inspection.

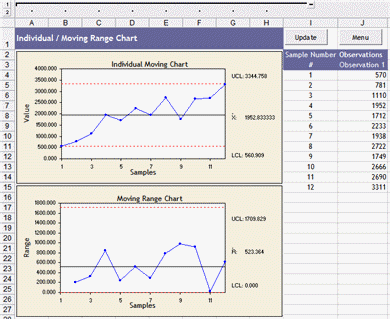

- Template Used: Process Control Sheet with SPC charts for dimensional tolerance.

Healthcare Services

- Process: Patient intake → Diagnosis → Treatment plan → Follow‑up.

- Template Used: SOP for infection control and a checklist for compliance with HIPAA.

Software Development

- Process: Requirement gathering → Sprint planning → Coding → Code review → Deploy.

- Template Used: Agile SOP with built‑in Definition of Done (DoD) and automated test coverage metrics.

Step‑by‑Step Implementation Guide

- Secure Leadership Commitment – Align the QMS with strategic goals.

- Map Core Processes – Use the Process Map template to capture current workflows.

- Define Quality Requirements – Document design and process specifications.

- Create SOPs & Control Sheets – Populate the templates for each mapped process.

- Train Employees – Conduct hands‑on workshops and provide cheat‑sheet reference guides.

- Monitor & Measure – Collect data daily using the control sheets; review weekly.

- Analyze & Improve – Apply root‑cause analysis (5 Whys, Fishbone) to variances.

- Document Changes – Update SOPs and maintain version control.

Tools & Resources to Accelerate Your QMS

Leverage ready‑made Excel templates and strategy toolkits to reduce set‑up time:

- Business Plan Template – Align your QMS with overall business objectives.

- Marketing Plan Template – Ensure product quality matches market promises.

- Financial Dashboard Excel – Track cost of quality and ROI of improvements.

- Balanced Scorecard Toolkit – Link process metrics to strategic performance.

Quick Checklist – Ready to Deploy

| Task | Completed? | Notes |

|---|---|---|

| Leadership sign‑off | ||

| Process map drafted | ||

| Design quality specs defined | ||

| SOPs written | ||

| Control sheets created | ||

| Team trained | ||

| First week data collected | ||

| Improvement meeting held |

Next Steps

Start building your process‑based QMS today with our Financial Dashboard Excel template to monitor cost of quality, and then download the Business Plan Template to embed your quality objectives into the company’s strategic plan.