Executive Summary

Traditional supply chain KPIs focused solely on speed and cost are failing in today’s volatile market. Companies now need adaptive “thinking” KPIs that measure responsiveness, risk mitigation, and real-time decision-making to survive disruptions.

Static efficiency metrics create fragile systems. Adaptive KPIs enable 30% faster recovery from supply chain disruptions according to Gartner research.

The Problem With Old-School KPIs

Traditional metrics like “cost per unit shipped” or “on-time delivery rate” worked when demand was predictable. Now:

- 73% of supply chain leaders report increased disruptions since 2023

- Inventory turnover ratios hide critical data about stockout risks

- Carrier performance scores ignore alternative routing options

These metrics create false confidence. A warehouse might hit 98% on-time shipments while carrying 40% excess safety stock nobody tracks.

What Makes KPIs “Thinking” Metrics?

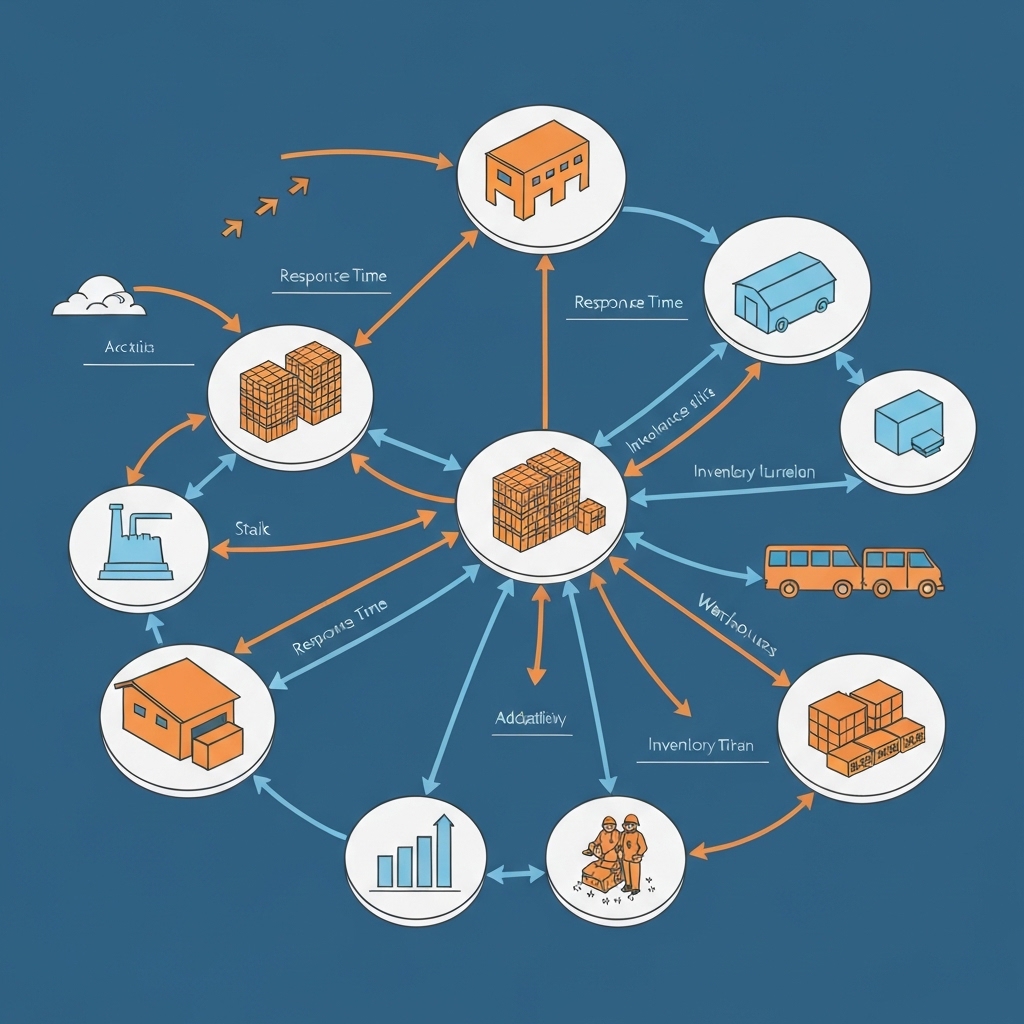

Adaptive KPIs combine three elements:

- Real-time data feeds from IoT sensors and shipping partners

- Scenario analysis showing how metrics change during disruptions

- Autonomous decision triggers for inventory rebalancing

Example: Dynamic inventory turnover ratio = (Cost of goods sold / Average inventory) with adjustment factors for supplier lead time volatility.

Key Adaptive KPIs to Track

Response Time to Disruption: How quickly your system reroutes shipments when a port closes

Inventory Agility Score: Percentage of SKUs that can be replenished within 72 hours

Collaboration Velocity: Time taken to resolve exceptions with suppliers through shared dashboards

Risk Exposure Ratio: (Value at risk from single-source suppliers) / (Total procurement spend)

Action Plan: Building Adaptive KPI Systems

Step 1: Map Blind Spots

Audit existing KPIs against last three years of disruptions. Where did metrics fail to predict problems?

Step 2: Connect Systems

Integrate warehouse management systems with supplier production schedules and customer demand forecasts.

Step 3: Create Red Flag Metrics

Define thresholds that trigger automatic alerts. Example: “If supplier lead time increases 15% AND alternative routes exist, initiate contingency plan.”

Case Study: Electronics Manufacturer

A mid-sized electronics firm replaced static metrics with adaptive KPIs:

- Added “Component Availability Score” tracking 10+ supplier regions

- Implemented dynamic safety stock formulas adjusting for geopolitical risks

- Created shared KPI dashboards with top 20 suppliers

Result: Reduced stockouts by 62% while lowering safety stock costs by $2.1M annually.

Things to Remember

Adaptive KPIs aren’t about adding more metrics. They’re about choosing metrics that create actionable insights when conditions change.

Start small: Pilot 1-2 adaptive KPIs in your most vulnerable supply chain segments. Use their performance to justify broader implementation.

What’s Next?

Next quarter, benchmark your KPI maturity against peers using Gartner’s supply chain metrics framework. Prioritize integration with partners who share your commitment to adaptive metrics.

Here’s your immediate action: Schedule a cross-functional workshop with procurement, logistics, and IT teams to identify your top 3 KPI weaknesses within 30 days.